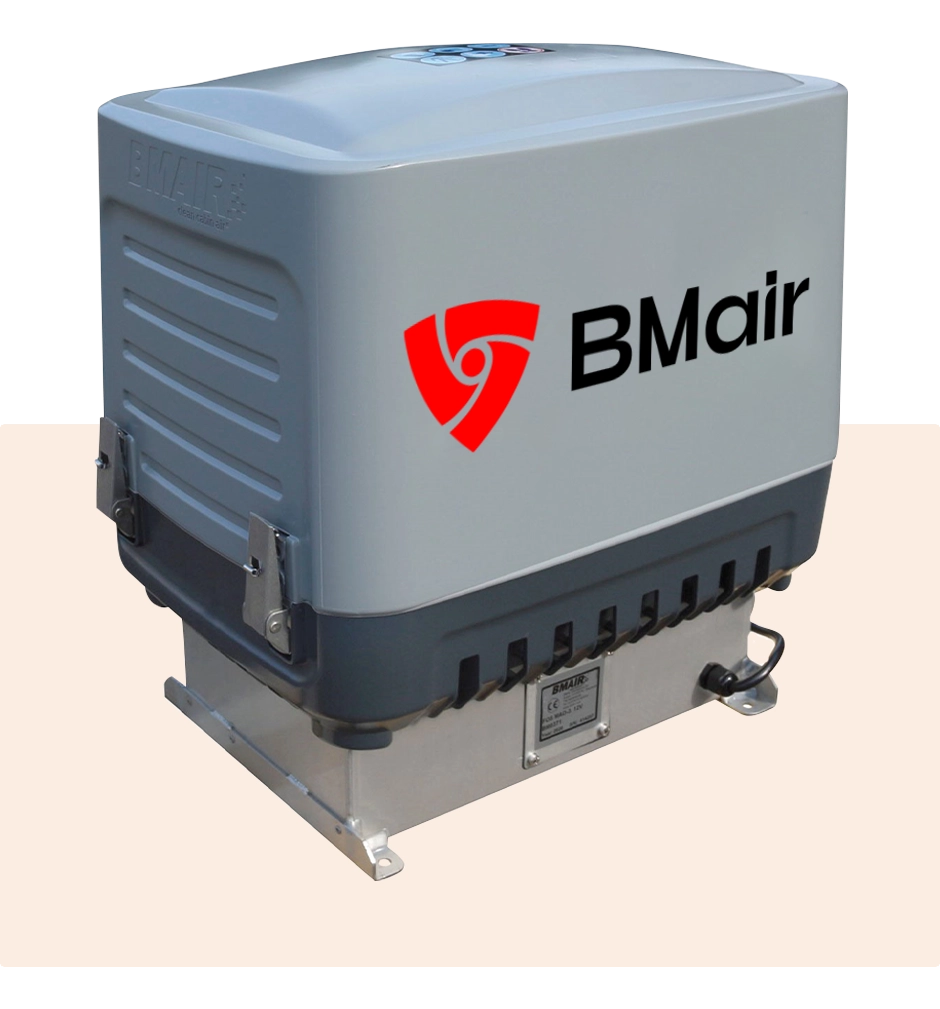

BMair MAO-3 Cab Guard

Specially designed for the increasing demand for compact and smart systems. Under the modern, robust, plastic housing is a uniquely shaped self-cleaning HEPA filter with incomparable capacity.

✔ Suitable for deck / fender mounting

✔ For standard & heavy workplace conditions

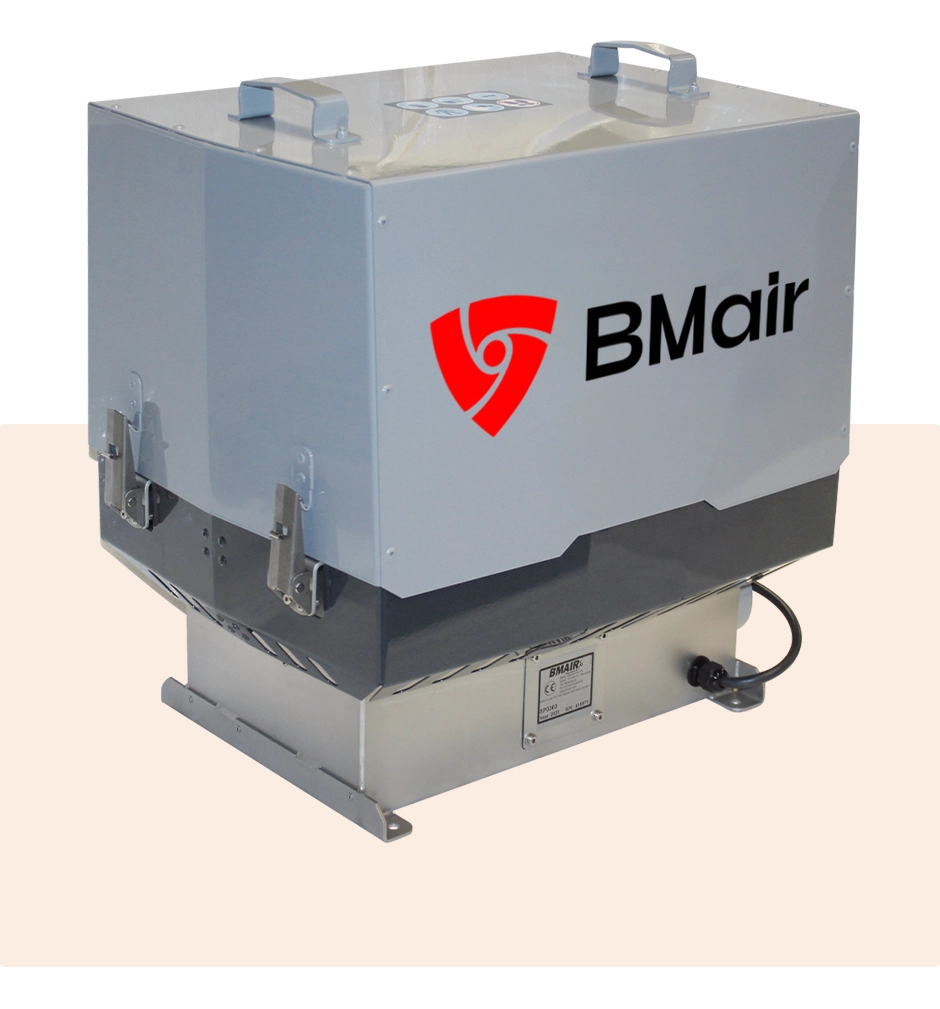

BMair MAO-3 Metal Cover

Specially designed for the increasing demand for compact and smart systems. Under the modern, robust, stainless steel housing is a uniquely shaped self-cleaning HEPA filter with incomparable capacity.

✔ Suitable for deck / fender mounting

✔ For standard & (extremely) heavy workplace conditions

BMair MAO-6HC

With its streamlined design and compact height, this system is exceptionally suitable for roof installations, without compromising on capacity.

✔ Suitable for roof mounting

✔ For standard & heavy workplace conditions

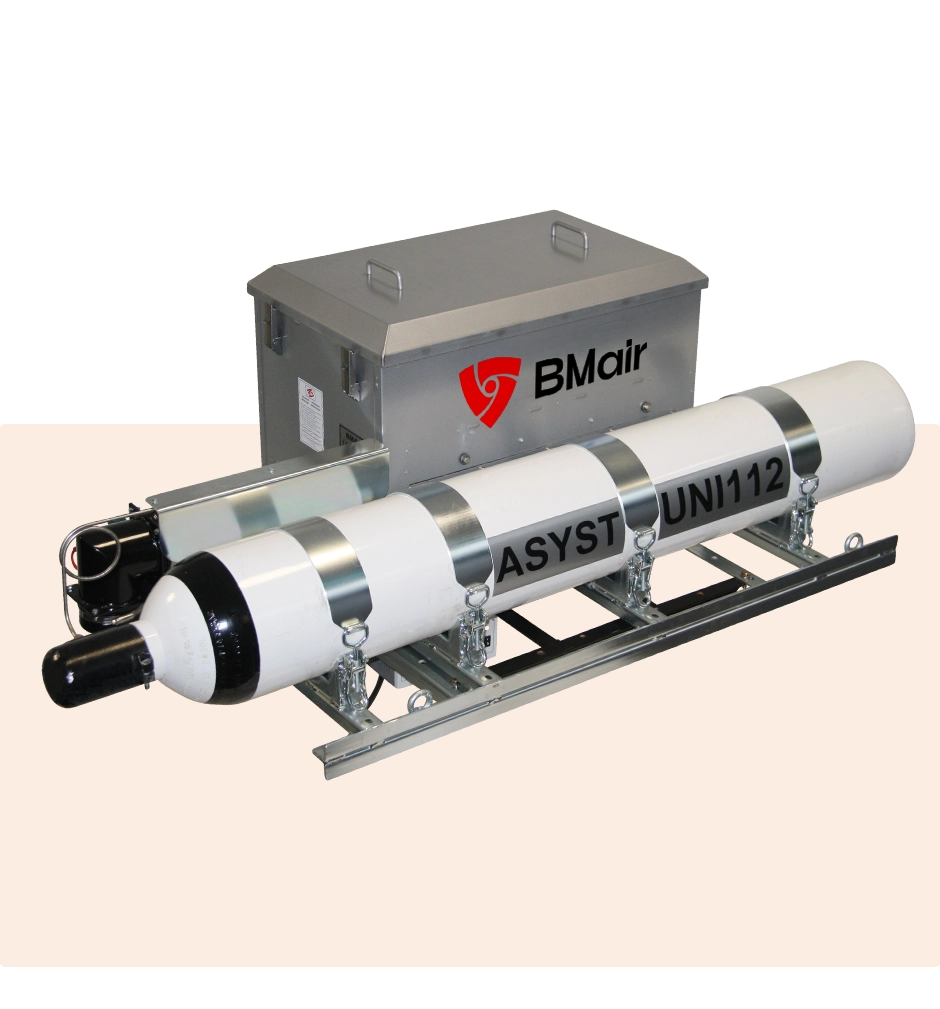

Bmair Asyst Uni 112

The patented breathing air assistant system BMAir ASYST allows you to continue working under safe conditions during extreme peak loads in the concentration of gases and vapours.

✔ Customized mounting location

✔ For extemely heavy workplace conditions

BMair F20

Compact, powerful and suitable for practically every construction machine. Despite its compact design, the F20 is characterised by its high HEPA filtration capacity.

✔ Suitable for deck / fender mounting

✔ For standard / heavy dusty workplace conditions

BMair F33

Get ready to revolutionize the way we fight unhealthy air with this stainless steel powerhouse engineered for the most demanding of environments.

✔ Suitable for deck / fender mounting

✔ For standard & (extremely) heavy workplace conditions