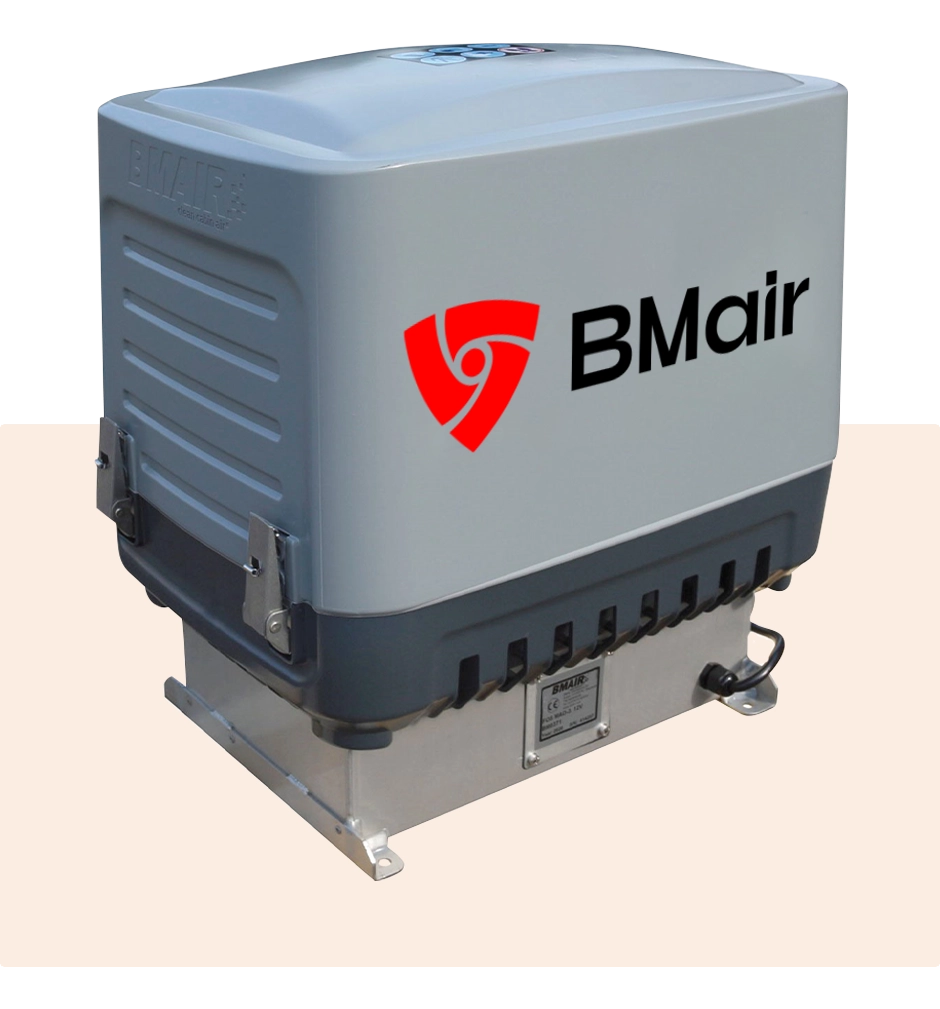

Our protective ventilation systems

As the market leader in Europe, we have the responsibility to redefine air purification. So we create a better and cleaner future together. Guarding any compromises on health.

Global standards provide a framework, but often vary in strictness. Conforming to regulations is therefore not the goal. No, BMair aims for the highest achievable standards. We achieve this by utilizing the latest technologies. Our team of engineers is dedicated to continuously improving BMair systems. Why? For the health of yourself or your personnel. With care the product range of BMair is curated, each designed for the best possible filtration in your sector.